Advantages of Three Pass Cylindrical Back Furnace Steam Boilers

Based on our 50 years of experience in the boiler manufacturing sector and the applications we have made, we see that the back furnace boilers are more efficient than the classical type cylindrical boilers. The advantages of the back furnace boilers that we mentioned in our offers compared to the classical type cylindrical boilers are summarized below

- In the classical type cylindrical steam boilers, there is a wet back chamber at the end of the furnace. Second pass tubes (short tubes) are welded to the front of the wet back. Since there is no wet back chamber in the back furnace steam boilers, the smoke tubes in both passes are welded to the front tube sheet and the rear tube sheet. For this reason, the boiler is more stable and the gas passage path is longer.

- The 2nd pass and 3rd pass tubes are of the same length in back furnace steam boilers. In this way, the flue gas path is longer.

- Since the flue gas path is longer in the back furnace steam boilers compared to the classical type cylindrical boilers, heat conduction is better, the flue gas outlet temperature is low and therefore the boiler efficiency is high.

- Since the back furnace does the wet back chamber task, the bottom blowdown of the boiler is healthier.

- Since the furnace size increases thanks to the back furnace, the flame length limitation is eliminated in the burners to be used. For this reason, back furnace boilers are also preferred by burner suppliers.

- In classical type cylindrical boilers, the furnace is usually in the middle axis of the boiler. In back furnace boilers, since the furnace is off-axis, the maintenance of the burner and the installation of gas duct armatures are easier.

- Since the explosion cover is off the axis of the furnace, it is not exposed to flame touch, so the explosion cover is not deformed.

Boiler production is inspected by internationally registered third party notified body companies and after the production is completed a CE certificate is obtained.

The 3-pass cylindrical back furnace steam boilers produced by our company bring the following advantages as liquid and/or gas fueled.

- Stable structure

- 3 pass

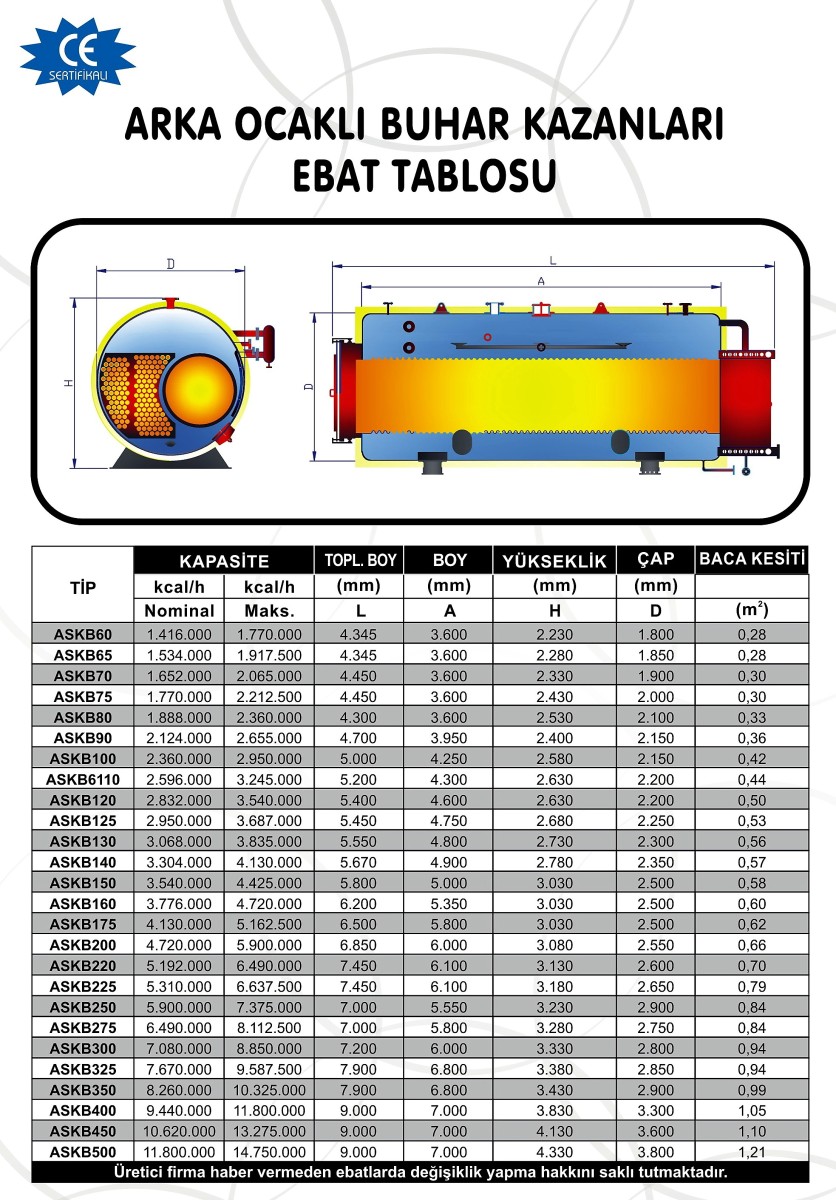

- 1.000 – 30.000 kg/h steam production

- 0.5 – 30 bar operating pressure

- High efficiency up to 91%

- Flame / smoke tube type

- Back furnace with water tubes

- Very low boiler back pressure

- Design in accordance with CE pressure vessels directive, TRD, EN and TSE norms

- Possibility to place a superheater in the back furnace

- Additional heating surface with back furnace

- Low flue gas temperature

- Longer flame length with special design

- Efficiency up to 95% with the addition of an economizer to the flue gas outlet

- High steam volume